Since 2021, global investment in nuclear fusion has rapidly increased. China's commercialization of controlled nuclear fusion is also showing an accelerating trend. China has initially formed a landscape with two major national projects and several commercial companies operating in tandem. The Economic Observer interviewed Chen Rui, CEO of Startorus Fusion, to discuss the development and challenges of controlled nuclear fusion commercialization.

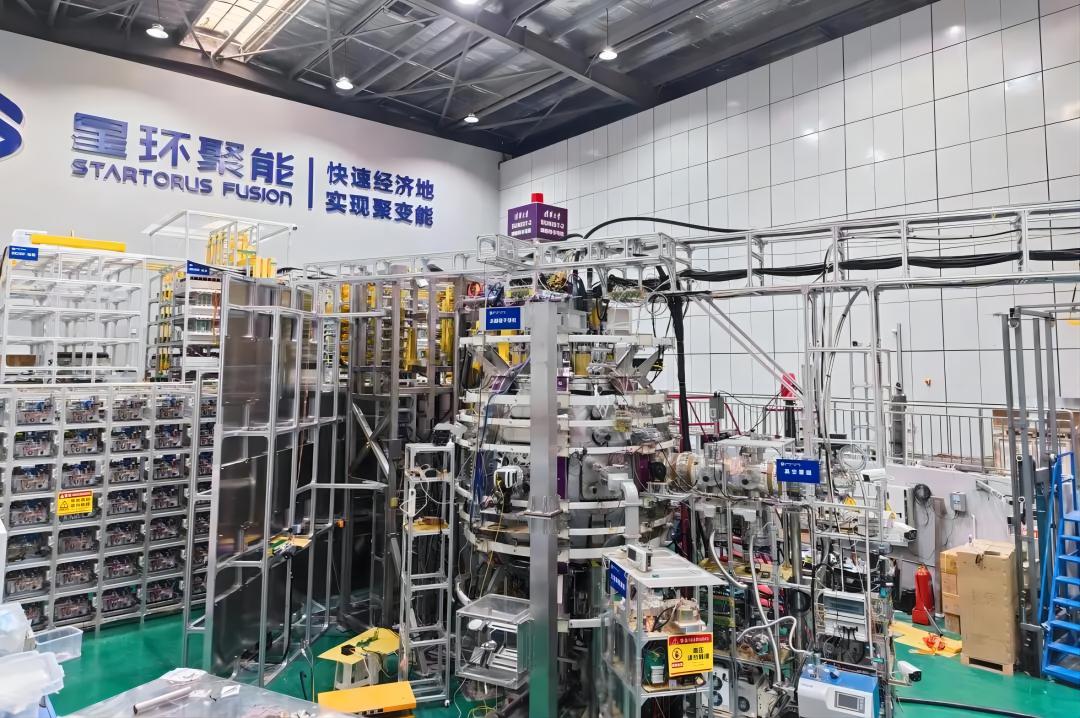

Startorus Fusion is a technology transfer project from Tsinghua University, with chief scientist Tan Yi overseeing the operation, maintenance, and upgrades of China’s first spherical tokamak, SUNIST, and possessing over 20 years of experience in magnetic confinement fusion research. By 2021, with the completion of its technical roadmap, the company’s establishment had become a natural progression.

Chen Rui pointed out that compared to national projects, commercial companies prioritize cost-effectiveness and speed while ensuring experimental safety and controllability. They are also more daring in adopting emerging technologies, aligning with Startorus Fusion's goal of achieving fusion energy rapidly and economically. The compact, miniaturized spherical tokamak fusion experimental device developed by the company effectively reduces material and construction costs, decreases project investment, and accelerates the pace of R&D iterations.

Mi Lei, founding partner of CASSTAR, noted that breakthroughs in small to medium-sized fusion devices have lowered the costs of controlled nuclear fusion systems, making entry into the market possible for commercial companies. Most importantly, the breakthroughs by various companies have brought the expectation for commercialization from several decades closer to about ten years. Shunwei Capital stated that with the development of fusion technology, the initial breakthrough from nothing to something has been achieved, and the challenges now lie not in fundamental science but in how to rapidly implement devices and iterate technologies. This is essentially an engineering issue, where commercial companies have the opportunity to excel in product iteration speed and cost control.

In September 2021, the U.S. fusion company CFS first incorporated high-temperature superconducting (HTS) materials into magnetic coils for a fusion experimental device, achieving a magnetic field of up to 20 tesla, with a central magnetic field reaching 12 tesla. In contrast, the central magnetic field of the ITER, which uses low-temperature superconducting materials, is only 5.3 tesla. Regarding CFS's breakthrough, Jin Zhijian, a long-term professor at Shanghai Jiao Tong University and founder and chairman of Shanghai Yixi Technology Development Co., stated, "This means that miniaturized fusion reactors will become possible, significantly reducing costs and, more importantly, greatly shortening the R&D cycle."

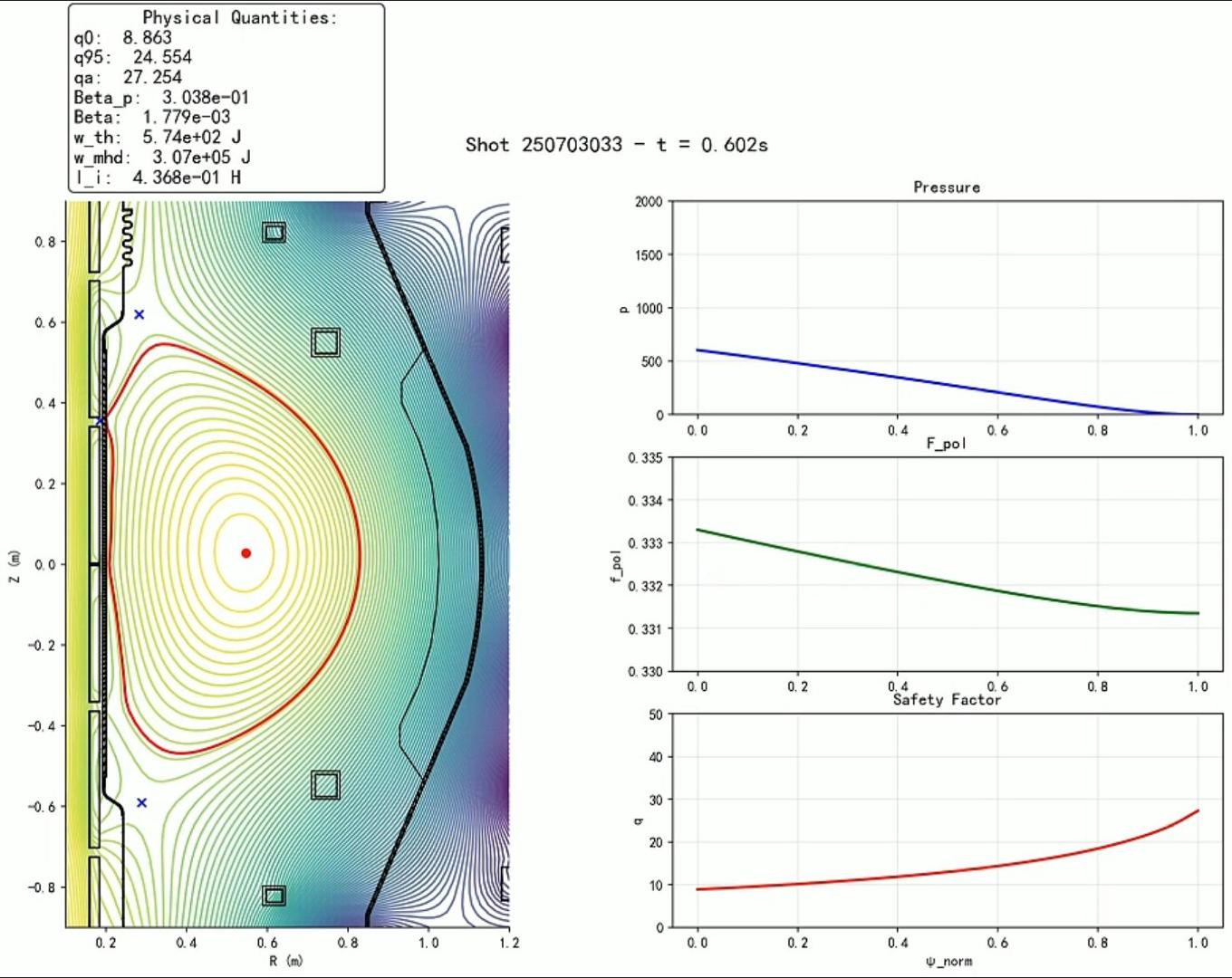

Chen Rui noted that, in addition to breakthroughs in HTS materials, the application of AI, 3D printing, and other new technologies has helped improve experimental efficiency, reduce the size of experimental devices, and lower experimental costs. It can be said that the development of fusion technology is necessarily led by progress across multiple technical fields. Startorus Fusion plans to complete two important steps in its development plan within the next decade. The first is to build the next-generation experimental device CTRFR-1 by 2027, which will continuously and stably heat plasma to 100 million degrees Celsius through a repetitive reconnection scheme to thoroughly validate engineering feasibility. The second is to take another 3 to 5 years to construct a commercial fusion demonstration reactor capable of generating electrical power.

The technical complexity and integration of fusion R&D are extremely high and span long cycles because the destination of utilizing fusion is to simulate the extreme temperature and pressure conditions of the sun's core on Earth, posing significant challenges to the limits of physics. An even more challenging aspect is that researchers cannot create a perfect experimental device all at once; they must go through multiple iterations, gradually approaching the final technical specifications. "It’s like someone who has never built a car cannot instantly produce a supercar," Chen Rui explained.

One characteristic of commercial companies is their ability to incorporate new technologies into each iteration while slightly improving performance metrics, thereby reducing the number of iterations and significantly shortening the R&D cycle. Chen Rui stated that commercial companies can innovate more flexibly, but all innovations come with risks. Finding a balance between risk and innovation is essentially a decision-making issue. "Different teams have different styles; some are conservative, while others are aggressive. There is no such thing as an optimal or singular solution."

In June 2024, Startorus Fusion achieved new progress - plasma temperature reaching expectations and plasma current hitting a new high, while the design of the CTRFR-1 device is nearing completion.

Click ‘Read More’ to view the Economic Observer .