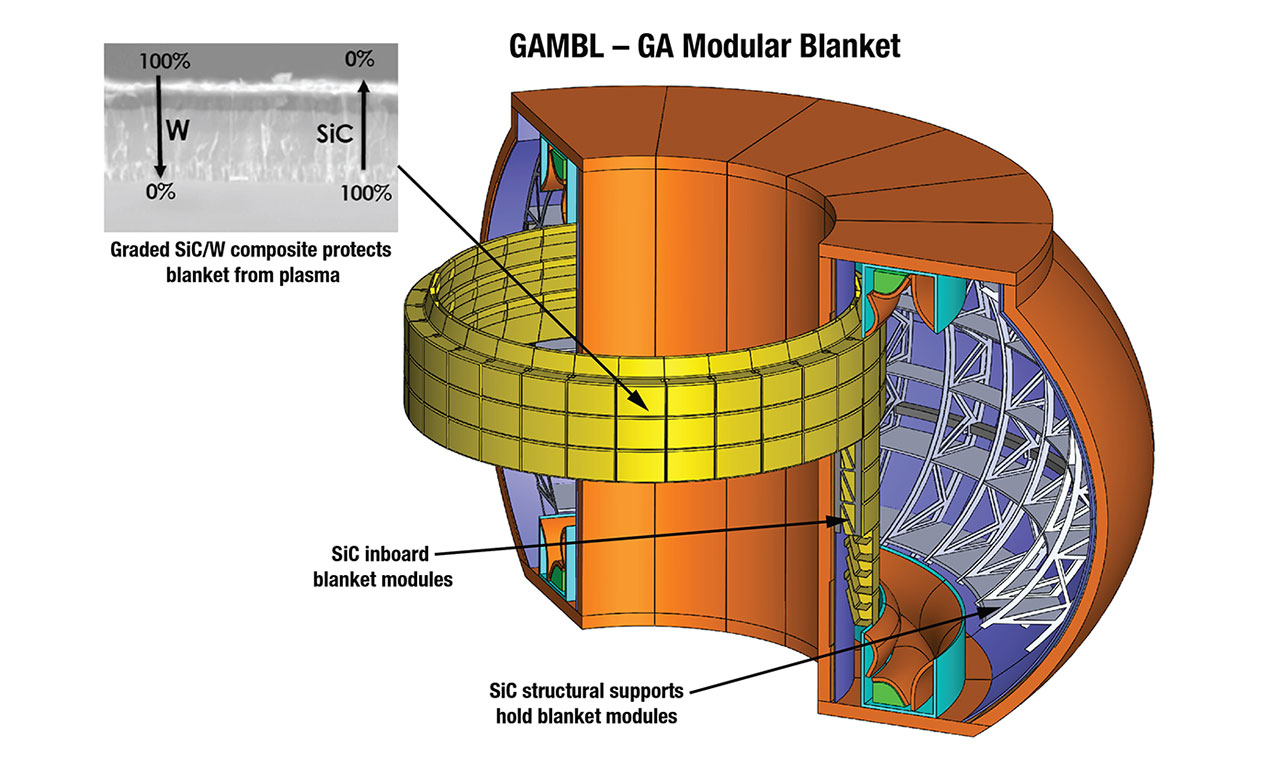

On July 13, researchers at General Atomics (GA) announced a new concept for advancing fusion energy using advanced Silicon Carbide (SiC)–based materials that can withstand the intense conditions within a high-power fusion device. Offering significant safety and environmental advantages, the GA Modular Blanket (GAMBL) concept will support the accelerated development of a fusion pilot plant capable of producing safe, clean, and always-on energy.

The above graphic shows a cut-away of a fusion device illustrating how the GAMBL (GA Modular Blanket) could be incorporated into a fusion pilot plant.

GAMBL uses SiC-based structures due to their inherent safety and high-temperature strength. The SiC/tungsten composite wall provides superior heat-removal capabilities and durability, and a modular approach enables fabrication using existing technologies. These advances allow for higher efficiency and less-expensive electricity.

GAMBL advances the design for the breeding blanket, a critical component of a fusion reactor that absorbs neutrons, produces heat, and creates tritium to make the fusion fuel cycle self-sufficient. It is described in an article published this month in the journal Fusion Engineering and Design. Many concepts for fusion power plants use "reduced-activation" steel for components like the blanket because it resists becoming radioactive better than conventional steels. Advanced materials such as SiC have even lower activation properties and are therefore viewed as superior solutions. SiC's ability to survive much higher temperatures than steel also means it can support more efficient electricity generation.

However, despite its excellent strength and durability, SiC has not been viewed as a long-term solution due to uncertainties about its material properties and its limited ability to contain the high-pressure helium (envisioned as a coolant fluid in many reactor designs). GAMBL overcomes these challenges by introducing several novel features, including engineered SiC-tungsten materials for interior surfaces of the tokamak. This allows for superior heat-removal capabilities and durability.

"Current near-term designs for prototype fusion reactors rely on steels, but SiC-based materials have unique advantages such as low activation, high-temperature strength, and an ability to couple to a highly efficient power conversion system," said Mark Tillack, who led the GAMBL design team. "GAMBL leverages the capabilities of SiC-based materials to deliver an inherently safe, environmentally friendly design."

Since the 2010s, GA has conducted a robust R&D program to develop SiC composites for fourth-generation fission reactors and accident-tolerant fuel rods. For fusion, GAMBL's simplified cooling system and absence of steel means the system can deliver much higher temperatures (>1000C vs ~500C) to the turbine-generators. This means much higher power-plant efficiency and less-expensive electricity compared to designs using low-activation steel.

Original Article:

General Atomics Advances Fusion Technology with Silicon Carbide (SiC)–Based Materials | General Atomics (ga.com)