As an important direction for China's future energy development, nuclear fusion technology has a significant impact on the country's energy security and sustainable development. Startorus Fusion, as an innovative enterprise dedicated to the commercial application and technological development of fusion energy, has recently made a series of significant progress in key fusion engineering and physics fields, including High-Temperature Superconductivity (HTS), repeated reconnection operation mode and non-inductive startup. These achievements not only provide solid support for high-power heating and stable operation of fusion devices but also mark a solid step forward for Startorus Fusion in realizing the grand goal of "quickly and economically achieving fusion energy."

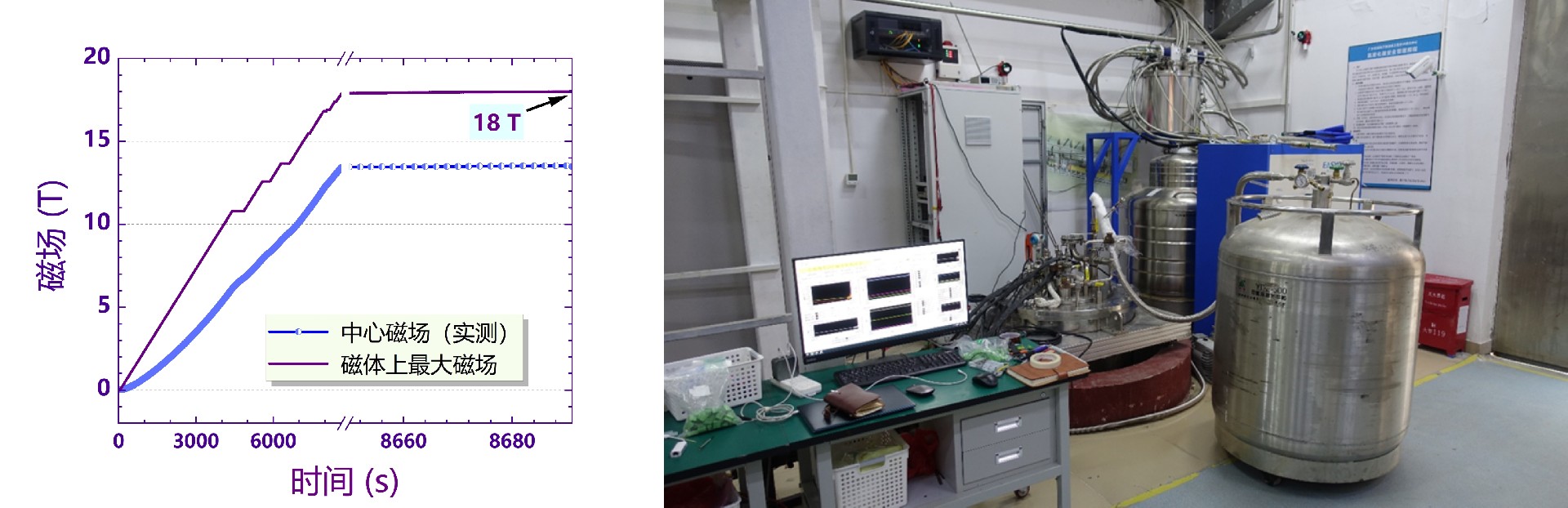

Compared to simple circular cross-section magnets, D-shaped magnets better match the shape of high-performance plasmas, which is a fundamental requirement for future fusion reactors. In collaboration with Tsinghua University, Startorus Fusion has successfully developed a prototype of a D-shaped high-temperature superconducting magnet, using high-temperature superconducting tapes from Shanghai Superconductor Technology Co., Ltd. The maximum field strength inside the magnet reaches 18T, which is currently the highest reported field strength for D-shaped magnets in the country. This 18T field strength fully satisfies the toroidal field strength requirements for achieving fusion conditions in a spherical tokamak device. The successful operation of this magnet lays a solid foundation for the design of the company's next-generation device. The achievement represents the rapid progress of Startorus Fusion's high-temperature superconducting team in magnet technology. Within a short span of six months, the company has completed the principle design, engineering manufacturing, and overall testing, once again demonstrating the company's efficient research and development, as well as engineering capabilities. Moving forward, the company will continue to optimize magnet design and operation plans, aiming to achieve the ambitious goal of 25T field strength.

Left image: Magnet test curve; Right image: Magnet test system

Startorus Fusion has also achieved stable operation of the world's first repeated reconnection technology. In November 2023, the company announced the successful implementation of the first active double-loop magnetic reconnection heating startup in China. Building upon this achievement, Startorus Fusion has now accomplished continuous plasma startup through magnetic reconnection in two consecutive discharge cycles. The successful realization of magnetic reconnection heating and repeated reconnection marks the complete engineering implementation of the core operation scheme of the SUNIST-2 device, which is a collaborative project between the company and Tsinghua University. Both the active magnetic reconnection heating and repeated reconnection operation are the first of their kind in China, providing a solid foundation for the successful operation of the CTRFR-1 device, which aims to achieve fusion conditions in the next generation.

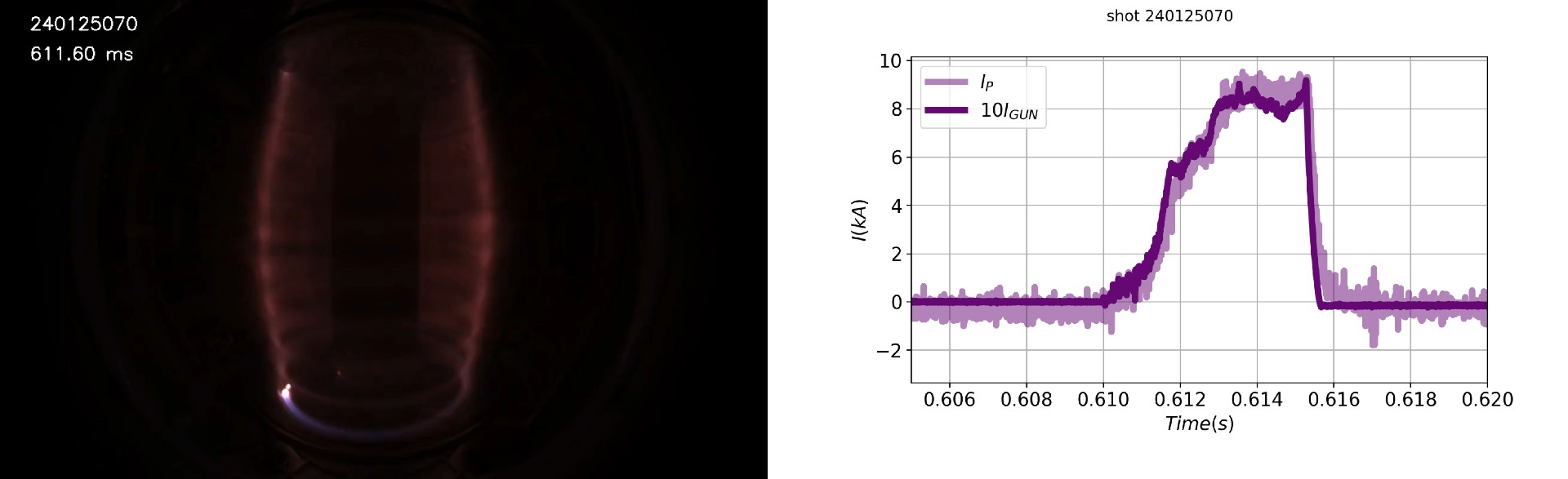

Additionally, Startorus Fusion has independently developed a local helicity injector with a compact structure and superior performance. This injector significantly boosts the initial plasma current and magnetic energy. The improvement in initial plasma current and magnetic energy greatly enhances the efficiency of magnetic reconnection heating, thereby multiplying the heating efficiency of the company's repeated reconnection scheme. The local helicity injector has become a crucial auxiliary device for the startup of the next-generation fusion device.

Left image: Local helicity injector startup; Right image: 10x gun current and plasma current

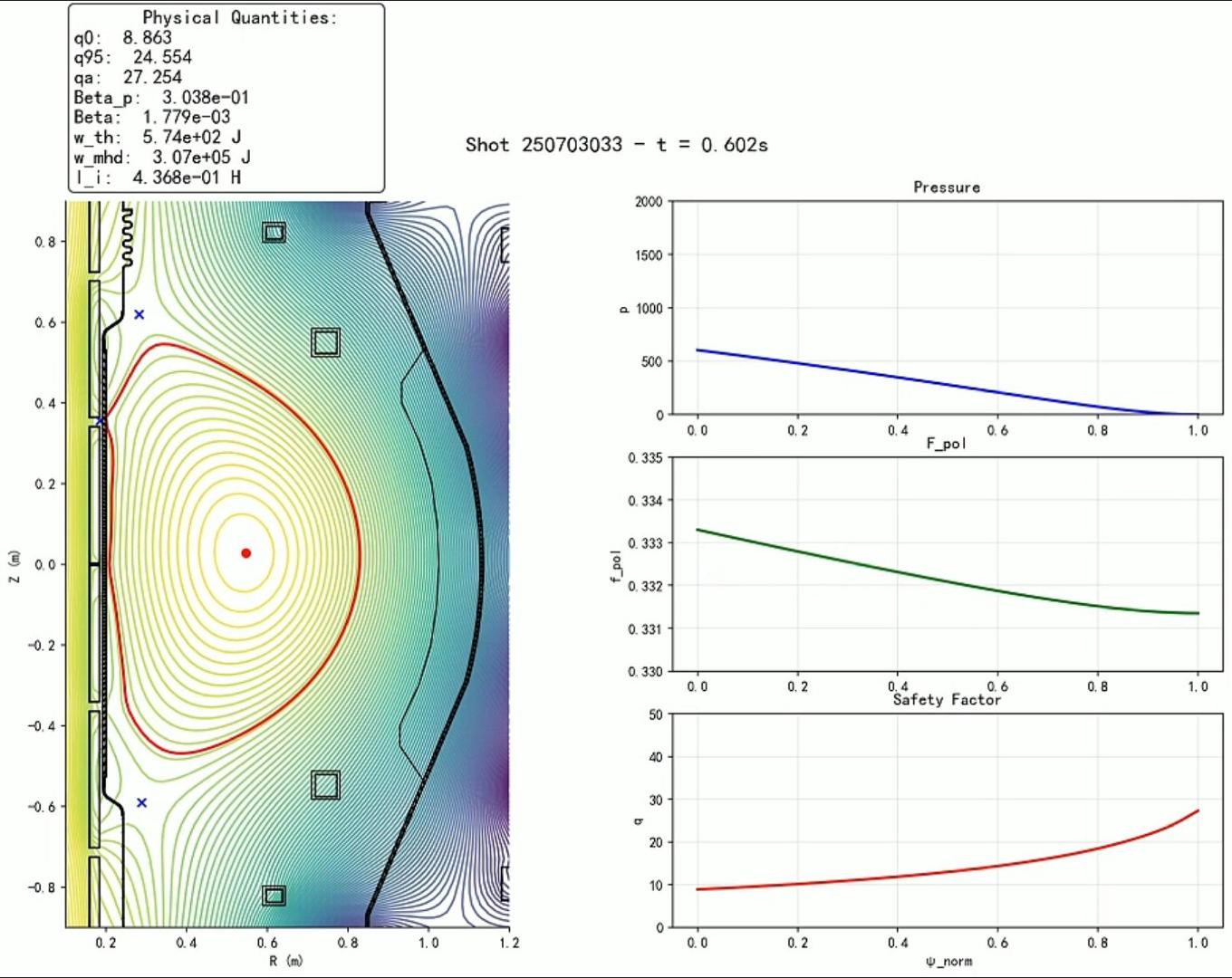

These achievements mark the substantial completion of the preliminary research and engineering preparations for the next-generation fusion-grade device, CTRFR-1. In 2023, Startorus Fusion successfully accomplished plasma double-loop startup, double-loop plasma magnetic reconnection heating, repeated reconnection operation, and the development of D-shaped toroidal field coils required for the future device. The company has already initiated physical simulations, equilibrium calculations, mechanical structure design, and other related work for the CTRFR-1 device. Moving forward, Startorus Fusion will continue to uphold its work style of "be brave enough to try and bear together" and its corporate culture of "actions speak louder than words, pioneering and innovating". The company will continuously refine and strengthen the cohesion and combat effectiveness of its team through engineering research and development, experimental exploration, and corporate care.

Appendix: Detailed Technical Description of Major Engineering Progress

1.Successful Development and Testing of D-shaped High-temperature Superconducting Magnet

Increasing the magnetic field is one of the key factors in rapidly and economically achieving fusion energy. Startorus Fusion, in collaboration with Tsinghua University, has recently achieved a significant milestone by successfully developing a prototype of a D-shaped high-temperature superconducting magnet. This development specifically targets the future requirements of fusion reactors. During the initial low-temperature current test, the measured field strength in the central region of the magnet reached 13.5T, with the highest field strength inside the magnet reaching 18T. These results meet the basic requirements set by Startorus Fusion's technical roadmap for magnets. The successful development of this magnet represents a significant advancement in high-temperature superconducting magnet technology and showcases strong research and engineering capabilities of the Startorus Fusion team.

The D-shaped magnet consists of eight double-pancake coils without insulation and incorporates a pre-stressed reinforcement structure and innovative assembly techniques. The design values of current operating points and electromagnetic stress are carefully considered, approaching the engineering limits. The team completed various tasks sequentially, including tape inspection, coil winding, magnet assembly, and low-temperature testing. Through these efforts, they have gradually mastered the core technology required for the development of high-temperature superconducting magnets for future fusion reactors. The team has successfully produced an advanced all-high-temperature superconducting D-shaped magnet, with support from the Advanced Energy Science and Technology Guangdong Provincial Laboratory during the magnet testing phase.

Moving forward, Startorus Fusion will continue to conduct targeted testing on this magnet prototype while simultaneously developing various high-temperature superconducting magnets for special purposes. These efforts will advance the engineering progress of the first pancake fusion-grade spherical tokamak toroidal magnet, further contributing to the development of fusion energy technology.

2.Experimental Validation of Repeated Reconnection Technology

Magnetic reconnection is an efficient method for heating plasma. In order to sustain fusion power output, Startorus Fusion properly designs the power supply and renders the reactor to operate in an operation mode similar to that of multi-stroke internal combustion engines. This allows for the repeated occurrence of magnetic reconnection, enabling the periodic generation of fusion power.

In January 2024, Startorus Fusion, in collaboration with the Tsinghua University team, successfully validated the engineering feasibility of repeated reconnection. This achievement was made possible through the use of a self-developed fully controllable magnet power supply and pre-ionization microwave source, in combination with precise adjustments to factors such as device gas injection, wall recycling, and induced eddy currents.

In the future, Startorus Fusion plans to further upgrade the energy storage capacity and current modulation capabilities of the magnet power supply. In the meantime, plasma shape control before and after reconnection will also be optimized, in conjunction with various non-inductive startup methods and ultra-fast gas injection and fueling techniques. These efforts aim to achieve higher performance and a greater number of cycles of repeated reconnection within a single discharge process.

3.Efficient Plasma Startup

To efficiently utilize the device's magnet capabilities and improve the performance of Ohmic discharge and magnetic reconnection heating in the plasma, Startorus Fusion, in collaboration with the Tsinghua University team, has developed a set of compact and high-performance local helicity injectors. These injectors, installed at the bottom of the device, work in conjunction with the extraction electrodes located at the top of the device.

Through precise adjustments to factors such as gas injection, extraction voltage, and magnetic field configuration, the team successfully initiated a plasma current of nearly 10kA in a non-inductive manner using local helicity injection, achieving a tenfold increase in plasma current. This was made possible by the efficient utilization of the plasma gun, located at the bottom of the device, in combination with the extraction electrodes at the top. The compact and high-performance design of the local helicity injectors, along with careful control of various parameters, enabled the successful startup of the plasma with significantly enhanced current, thereby improving the overall performance of the fusion device.